Class b cdl pre trip inspection list – The Class B CDL Pre-Trip Inspection List is an essential tool for ensuring the safety and compliance of commercial vehicles. This comprehensive guide provides a step-by-step walkthrough of the inspection process, highlighting the critical components to check, the equipment required, and the importance of reporting and documentation.

By adhering to the guidelines Artikeld in this guide, drivers can minimize the risk of accidents, breakdowns, and legal liabilities, while maximizing the efficiency and productivity of their vehicles.

General Overview: Class B Cdl Pre Trip Inspection List

A Class B CDL Pre-Trip Inspection List is a comprehensive checklist used by drivers of commercial motor vehicles (CMVs) with a Gross Vehicle Weight Rating (GVWR) between 26,001 and 33,000 pounds, or those towing a trailer with a GVWR of more than 10,000 pounds, to ensure the safe operation of their vehicle.

Pre-trip inspections are crucial for identifying any potential mechanical issues, safety hazards, or other defects that could compromise the safety of the driver, passengers, and other road users. By thoroughly inspecting the vehicle before operating it, drivers can proactively address any problems, reducing the risk of accidents, breakdowns, and costly repairs.

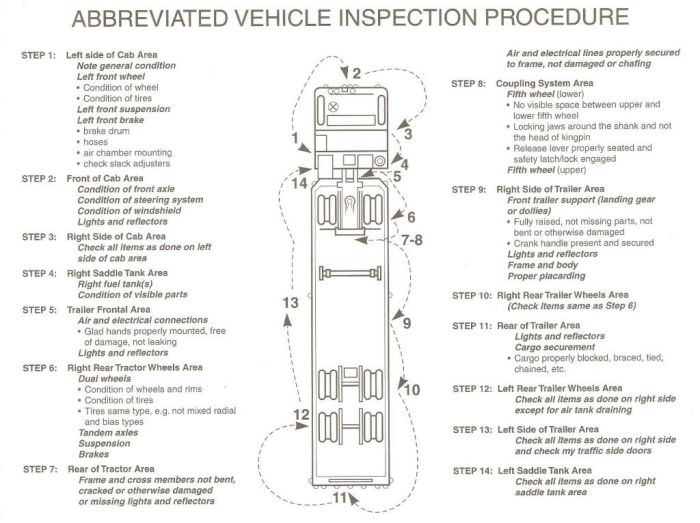

Inspection Procedures

A thorough pre-trip inspection is crucial for ensuring the safe and efficient operation of a commercial motor vehicle. By following a step-by-step guide and carefully checking various vehicle components, drivers can identify potential issues and take necessary corrective actions before operating the vehicle.

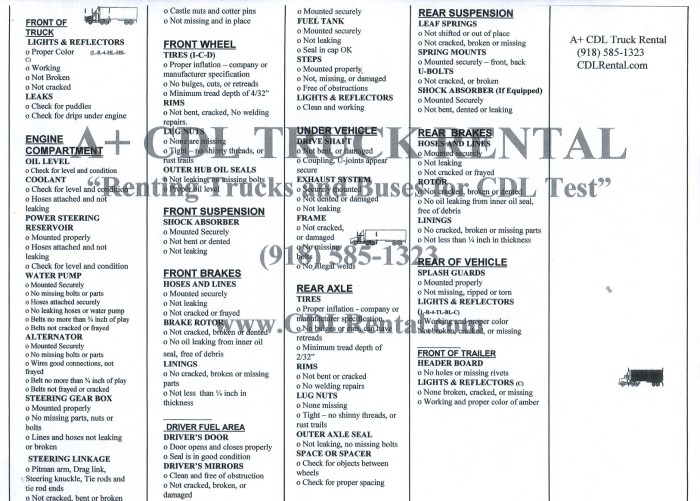

Exterior Inspection

The exterior inspection involves examining the vehicle’s exterior components for any damage, leaks, or other issues that may affect its operation or safety.

- Tires and Wheels:Check tire pressure, tread depth, and overall condition. Inspect wheels for cracks, dents, or other damage.

- Lights:Ensure all lights (headlights, taillights, turn signals, brake lights, etc.) are functioning properly and are clean.

- Body and Frame:Inspect the vehicle’s body for dents, scratches, or rust. Check the frame for any cracks or damage.

- Mirrors:Ensure all mirrors are clean and properly adjusted to provide clear visibility.

- Fluid Levels:Check fluid levels for engine oil, coolant, brake fluid, and power steering fluid. Ensure levels are within the recommended range.

Interior Inspection

The interior inspection focuses on the driver’s compartment and ensures that all controls, gauges, and safety equipment are in proper working order.

- Seat and Seat Belt:Adjust the seat for proper reach and visibility. Ensure the seat belt is in good condition and functions properly.

- Gauges and Controls:Verify that all gauges (speedometer, tachometer, fuel gauge, etc.) are functioning correctly. Check the operation of switches, knobs, and levers.

- Horn and Windshield Wipers:Test the horn and ensure windshield wipers are in good condition and functioning properly.

- Emergency Equipment:Check the presence and functionality of emergency equipment such as a fire extinguisher, first aid kit, and reflective triangles.

- Mirrors and Visibility:Ensure all mirrors are properly adjusted and provide clear visibility. Check for any obstructions or blind spots.

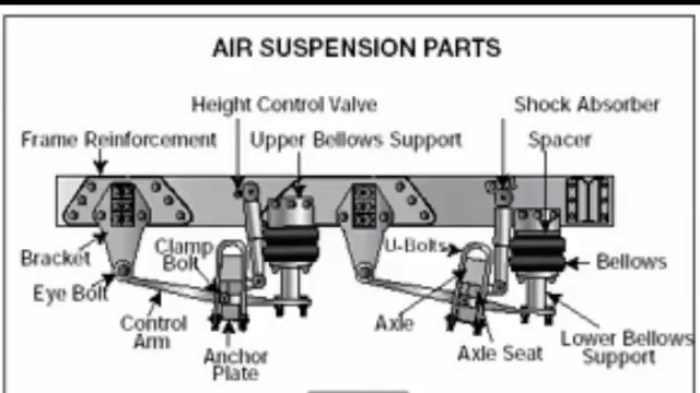

Undercarriage Inspection

The undercarriage inspection involves examining the vehicle’s underside for any leaks, damage, or other issues that may affect its performance or safety.

- Driveline and Suspension:Check the driveline (driveshaft, differential, axles) for any leaks or damage. Inspect suspension components (springs, shocks, bushings) for wear or damage.

- Exhaust System:Examine the exhaust system for leaks, cracks, or damage. Ensure it is properly secured.

- Fuel System:Check the fuel lines and tank for any leaks or damage. Ensure the fuel cap is securely tightened.

- Brake System:Inspect brake lines, hoses, and pads for wear or damage. Check the brake fluid level and ensure it is within the recommended range.

Required Equipment

Conducting a thorough pre-trip inspection requires having the necessary tools and materials. These items enable drivers to efficiently and effectively assess the condition of their vehicles, ensuring their safety and the safety of others on the road.

The essential equipment for a pre-trip inspection includes:

- Flashlight

- Measuring tape or ruler

- Tire pressure gauge

- Wrench

- Screwdriver

- Hammer

- Safety glasses

- Gloves

- Clipboard and pen

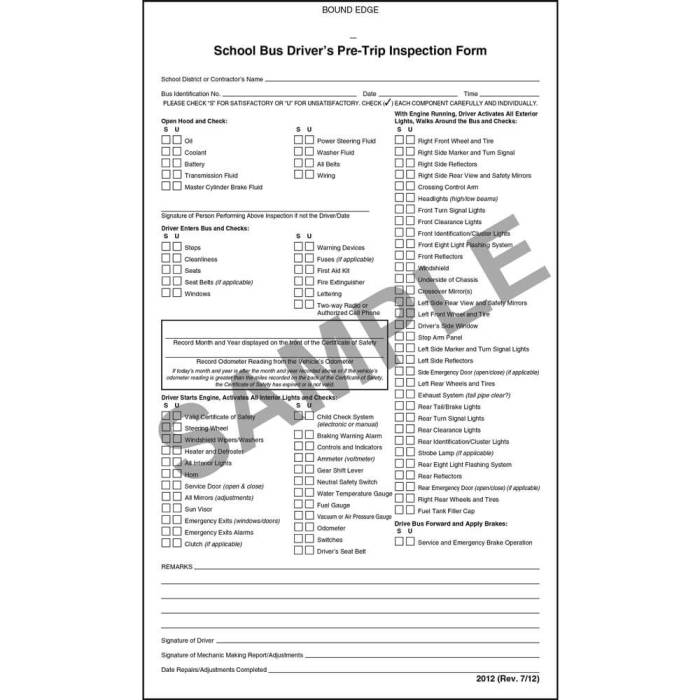

Reporting and Documentation

Thorough reporting and documentation of pre-trip inspection findings are essential for maintaining vehicle safety, regulatory compliance, and liability protection.

Accurate and timely documentation serves as a record of the inspection’s findings, allowing for future reference, tracking of repairs, and demonstrating due diligence in the event of an accident or incident.

Inspection Records

Inspection records should be created and maintained for each vehicle and include the following information:

- Vehicle identification (VIN, license plate number)

- Date and time of inspection

- Name of inspector

- Detailed description of all inspection findings, including any defects or deficiencies

- Actions taken to address defects or deficiencies (repairs, replacements, adjustments)

- Signature of inspector

Safety Considerations

Pre-trip inspections are critical for ensuring the safety of commercial motor vehicles and their drivers. During these inspections, it is imperative to adhere to strict safety precautions to mitigate potential hazards and maintain a safe working environment.

Some of the key safety considerations to observe during a pre-trip inspection include:

Personal Protective Equipment (PPE), Class b cdl pre trip inspection list

- Wear appropriate PPE, including gloves, safety glasses, and high-visibility clothing, to protect against potential hazards such as sharp edges, hazardous fluids, and moving parts.

- Ensure that PPE is in good condition and fits properly.

Vehicle Stability

- Park the vehicle on a level, stable surface to prevent it from rolling or shifting during the inspection.

- Engage the parking brake and chock the wheels to ensure the vehicle remains stationary.

Electrical Hazards

- Disconnect the battery before performing any electrical inspections or repairs to prevent electrical shocks.

- Use insulated tools and wear appropriate PPE when working with electrical components.

Fire Hazards

- Be aware of potential fire hazards, such as fuel leaks, electrical shorts, and hot exhaust components.

- Carry a fire extinguisher in case of emergencies.

Moving Parts

- Be cautious of moving parts, such as belts, pulleys, and fans.

- Never attempt to inspect or repair moving parts while the engine is running.

Environmental Hazards

- Be aware of environmental hazards, such as slippery surfaces, uneven terrain, and extreme weather conditions.

- Take appropriate precautions to minimize the risk of slips, falls, or exposure to hazardous substances.

Legal Compliance

Conducting pre-trip inspections is a legal requirement for commercial vehicle drivers. These inspections ensure that vehicles are in safe operating condition before being driven, reducing the risk of accidents and protecting drivers, passengers, and other road users.

The Federal Motor Carrier Safety Administration (FMCSA) requires drivers to perform pre-trip inspections before operating any commercial motor vehicle (CMV) with a gross vehicle weight rating (GVWR) of 10,001 pounds or more.

Consequences of Failing to Conduct Proper Inspections

- Fines and penalties:Drivers who fail to conduct proper pre-trip inspections may be fined or penalized by law enforcement.

- Vehicle impoundment:Vehicles that are found to be unsafe during a pre-trip inspection may be impounded until repairs are made.

- Loss of driving privileges:Drivers who repeatedly fail to conduct proper pre-trip inspections may have their driving privileges suspended or revoked.

- Civil liability:Drivers who fail to conduct proper pre-trip inspections and cause an accident may be held liable for damages.

Best Practices

To ensure thorough and efficient pre-trip inspections, industry best practices emphasize the following:

Adopting a systematic approach, utilizing checklists and inspection forms, can streamline the process and minimize the risk of missing critical components.

Optimizing Inspection Techniques

- Visual Inspection:Carefully observe all components, paying attention to signs of damage, wear, or leaks.

- Hands-On Inspection:Physically touch and manipulate components to assess their functionality and stability.

- Functional Testing:Activate components and systems to verify their proper operation.

- Documentation:Record all inspection findings, including any defects or potential issues.

Training and Resources

Pre-trip inspections are a critical component of safe and efficient commercial vehicle operation. Proper training is essential to ensure that drivers are able to conduct thorough and accurate inspections, identify potential defects, and make informed decisions about the safety of their vehicles.

There are numerous training programs and resources available to help drivers learn the proper procedures for pre-trip inspections. These programs may be offered by commercial driving schools, community colleges, or private training providers.

Training Programs

- Classroom instruction:Covers the theoretical aspects of pre-trip inspections, including the components and systems to be inspected, common defects to look for, and the proper procedures for reporting and documenting findings.

- Hands-on training:Provides practical experience in conducting pre-trip inspections on actual commercial vehicles, under the guidance of a qualified instructor.

- Online training:Offers flexibility and convenience, allowing drivers to learn at their own pace and schedule. However, online training should be supplemented with hands-on experience to ensure proficiency.

Resources

- FMCSA regulations:Provide detailed guidance on the requirements for pre-trip inspections, including the components to be inspected and the frequency of inspections.

- Commercial vehicle manufacturers:Offer specific inspection procedures and maintenance schedules for their vehicles.

- Industry organizations:Such as the American Trucking Associations (ATA), provide resources and training materials on pre-trip inspections.

Drivers are encouraged to seek out training and resources to enhance their knowledge and skills in conducting pre-trip inspections. By doing so, they can improve the safety and reliability of their vehicles, reduce the risk of accidents, and comply with legal requirements.

FAQ Compilation

What is the purpose of a Class B CDL Pre-Trip Inspection List?

The purpose of a Class B CDL Pre-Trip Inspection List is to ensure that commercial vehicles are in safe and proper operating condition before being driven. It helps identify potential defects or issues that could affect the vehicle’s performance or safety.

What are the key components to check during a pre-trip inspection?

Key components to check during a pre-trip inspection include: tires, brakes, lights, fluid levels, mirrors, and any other safety-critical systems or components.

What equipment is required for a pre-trip inspection?

Essential equipment for a pre-trip inspection includes: a flashlight, tire pressure gauge, fluid level dipsticks, and any other tools or materials necessary to check the specific components of the vehicle.